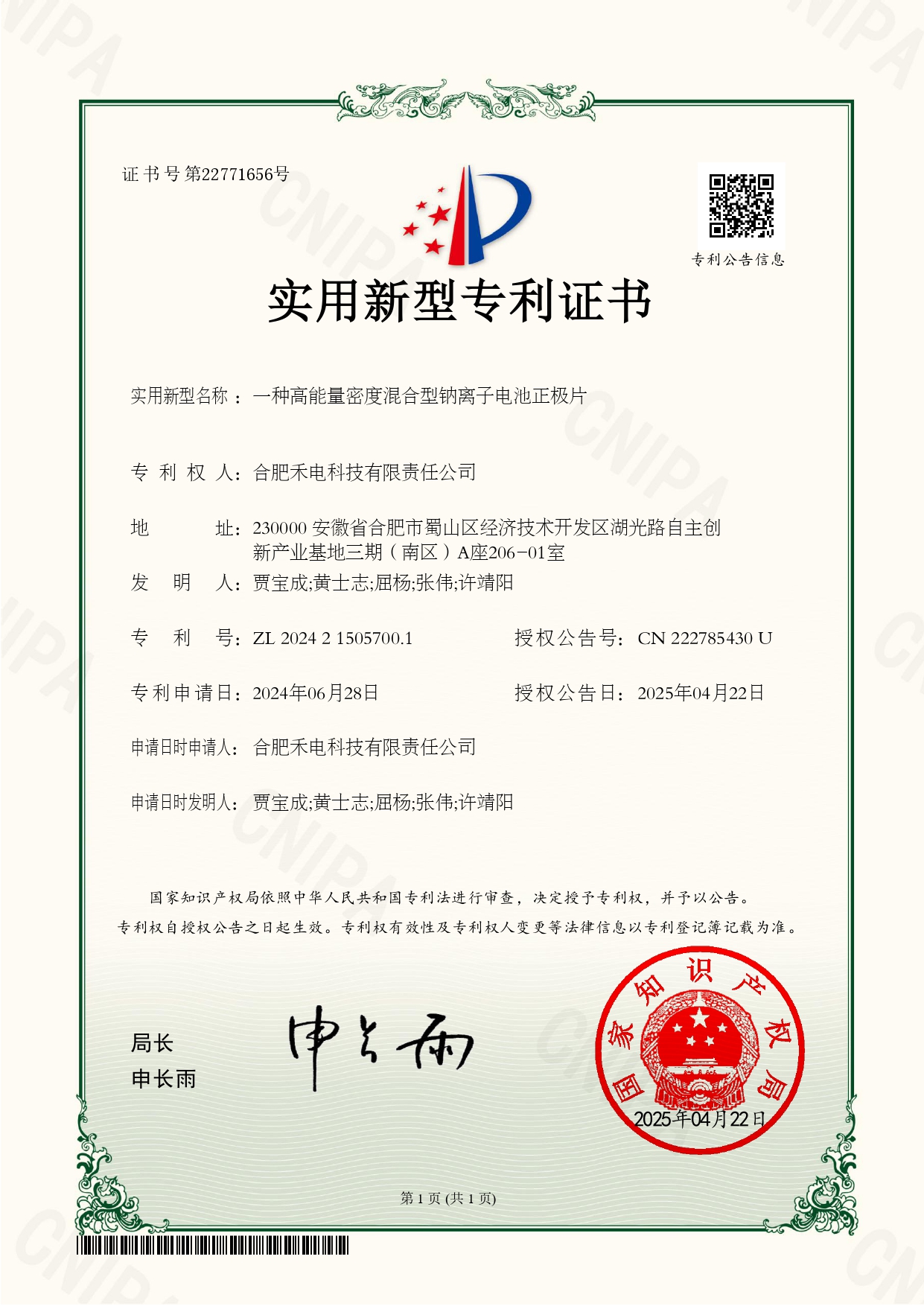

Core Technology

Focus on polyanion materials with high safety characteristics. These materials have significant advantages such as wide availability of resources, low raw material prices, and excellent rate performance.

-

Carbon coating technology

It can promote the transmission of electrons in materials and improve the charge-discharge rate and energy efficiency of batteries. -

Anion/cation regulation technology

Effectively improving the electrical conductivity, specific capacity, cycling stability and other properties of materials. -

Nanotechnology

Shortening the ion diffusion path, which enables better rate performance and cycling stability. -

Unique polyanion compound system

Stable three-dimensional structure, extending the cycle life of the battery

RTC

Innovation Mechanism

-

Innovative cooperation model

Innovative cooperation model

The company explores diverse R&D models and sets sodium - ion tech standards. Via seminars, it shares knowledge, integrates resources, and builds an open ecosystem for innovation and industrial growth. -

Core technological breakthrough

Core technological breakthrough

It innovates electrolyte formulations to improve cell cycle stability and thermal performance. Patented technologies solve high - cost and short - lifespan problems in sodium - ion batteries. -

Advanced R&D platform

Advanced R&D platform

To achieve efficient collection and analysis of R&D data, providing a solid foundation for rapid product iteration and process optimization. -

R&D team capabilities

R&D team capabilities

Leveraging PKU's resources, the company built an elite R&D team of doctors. Specialized in battery tech, they partner globally, tackle challenges, and drive innovation.